|

|

|

|

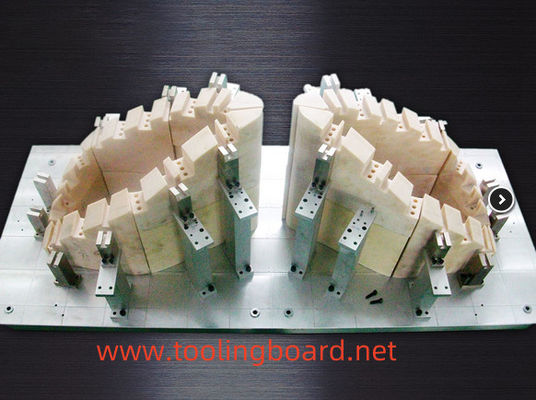

How to choose the right tooling boards for styling,modeling,tooling application

|

Product Details:

Payment & Shipping Terms:

|

| Hardness: | Shore D 0~85 | Stability: | Dimensionally Stable |

|---|---|---|---|

| Machinability: | Easy To Hand Carve Or CNC Processing | Applications: | Styling, Prototyping, Modeling, Tooling |

| Dimension: | Customizable | Material: | Polyurethane |

How to choose the right epoxy and pu tooling boards for styling,modeling,tooling application?

There are so many different brands and model number for tooling boards, people often take below key physical properties for consideration:

1. Density - the higher the density the more robust the tooling board, meaning finer details are machined easily. Lower-density tooling boards are suitable for creating models and prototypes as they are easy to shape.

2. Temperature and Coefficient of Thermal Expansion (CTE) - The lower the CTE, the less the tooling board will expand as temperatures increase. Choosing a board material with low CTE ensures precision and consistency in the mould and checking fixture.

3. Dimensional stability – Dimensional stability is the key factor. Tooling boards with excellent dimensional stability reduce the risk of expansion or shrinkage and maintain their original shape throughout manufacturing and subsequent use.

4. Surface finish – the surface finish directly impacts the look of the final part. Materials that boast a great surface finish remove the risk of defects and improve the overall durability of the tool.

5. Color- some people like to choose brown,blue, green, other prefer beige, ivory,grey,or red.

![]()

Contact Person: Jack

Tel: +86-15975552099

-

Professional Low Density Model Making Board, High Density Mold Making Board Material

-

Casting Foundry Mould Multi Colour Cnc Machinery Epoxy and PU Tooling Board

-

ZK high quality modeling and tooling boards with cheap price,similar to Renshape/Rampf raku/rubix/sika axson/base/necuron/ebalta/obo tooling boards

-

ZK150 ZK250 ZK350 low density modeling and tooling board, used for make patterns and models

-

Medium density polyurethane model board ZK651, fine surface structure, suitable for architectural models and luxury furniture models

-

PU Foam Board, Model Board, Tooling Board and Blocks from Dongguan ZEEK New Materials Co., Ltd